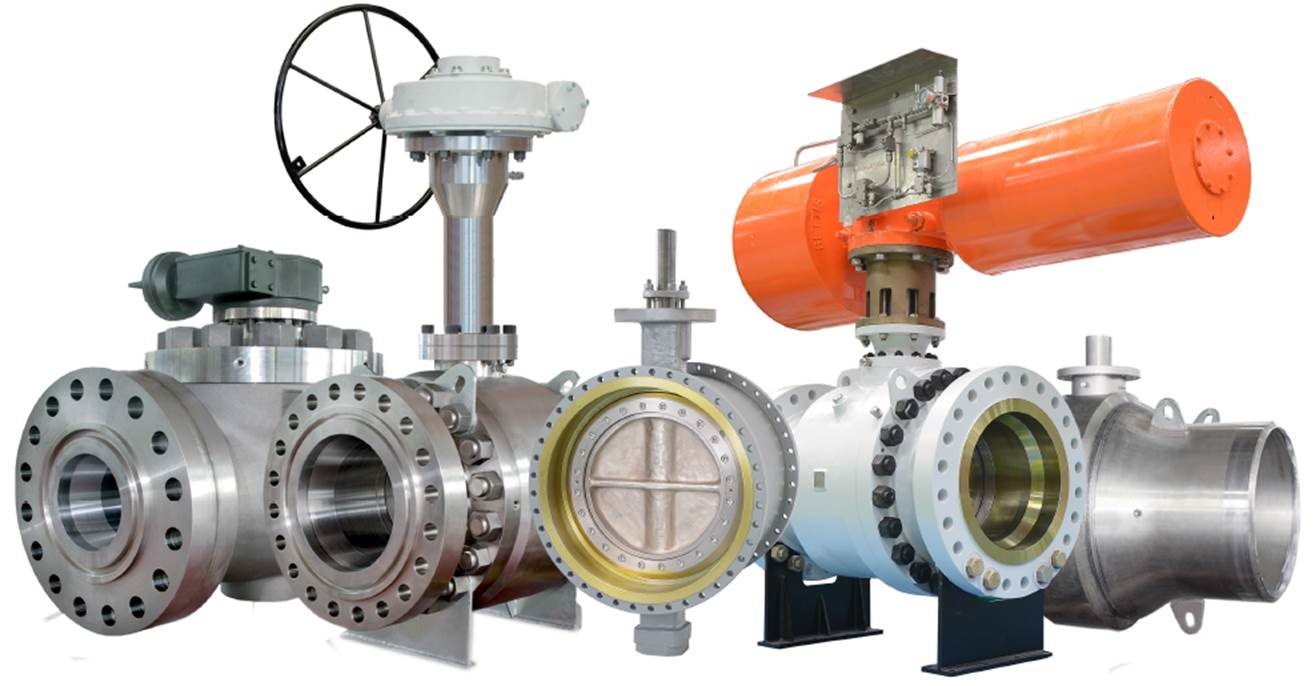

As the name suggests, ball valves are valves that use a ball to control the flow of substances from one opening to the next. They are easy to operate and repair as they contain a simple structure. These valves work by allowing the hole to be open, blocked, or open partially to regulate the flow of gas/liquid. Ball valves are the ideal choice for using with gases as they are able to offer better sealing.

They are very versatile as they support pressures up to 700 bars and temperatures up to 200°C and sizes typically range from 0.5 cm to 30 cm. They are designed with special measures that permit only a 90-degree rotation which is required for the opening and closing of ball valves. These valves are a notable industrial choice because of their reliable and air-tight sealing when in the closed position.

Why use a Ball Valve?

The major advantage of a globe valve is, it does not leak as much as other valves. Globe Valves are among the most popular type of valves used in various applications. Globe valves are composed of a baffle that splits the inside of the pipe, which is typically parallel to the pipe's length. They are named for their spherical body shape with the two halves of the body being separated by an internal baffle.

These valves are similar to gate valves and use linear motion to throttle flow. They are used to control the flow in a pipeline and they regulate by the position of a movable disk (or plug) in relation to the stationary ring seat. It consists of a movable disk-type element and a stationary ring seat in a generally spherical body.

Why use a Globe Valve?

Butterfly Valves are designed to regulate flow, but with limited control capability. Butterfly valves are configured to operate electronically, manually or pneumatically. Butterfly valves are easily operated by rotating a handle 90 degrees.

It consists of a metal disc in the body of the valve which is positioned perpendicular to the flow in the closed position. Regulation of liquid flow can be allowed through intermediate rotations.They can be used for a broad range of applications within water supply, wastewater treatment, fire protection and gas supply, in the chemical and oil industries, in fuel handling systems, power generation etc. These valves can be operated by handles, gears or actuators according to specific needs.

Why use a Butterfly Valve?

Industrial valves are devices that are used to regulate liquids, gases, and slurries. The flow of liquids or gases can be controlled using these valves. This can be done through pipes and other passageways by opening, closing, and partially obstructing the passageway or pipe.

WhizzImpex is engaged in providing our esteemed customers with a comprehensive range of Industrial Valves that are suitable for water, air, oil, liquid gas & petroleum gas etc. and widely used in cement industry & marine sector. Our valves are manufactured by our experts at par with the international standards of quality; well-recognized for its diverse features, this range is available in various specifications and can also customized on client’s demands.

Whizzimpex had always proven to be a trusted and reliable partner in offering the Industrial Valves to Some of the different types of Industrial Valves we manufacture include:

Gate valves are used for various purposes and they can be seen commonly in homes and commercial centers. Gate Valves are designed to serve as isolation valves. Different materials such as stainless steel, cast iron, alloy steel, forged steel etc are used to manufacture these valves. These valves help to control the flow of liquid through the pipes. To start or stop the water flow or any other kind of liquid, these valves are affixed to the pipelines.

Gate valves are used to either halt or start the flow of water. Functioning of gate valves includes the lifting of a circular of the rectangular gate out of the fluid path. When gate valves are open, there will be nothing to obstruct the flow as the pipeline diameter and gate have the same opening. The valve size can be determined with this bore diameter.

Why use a Gate Valve?